September 16, 2025

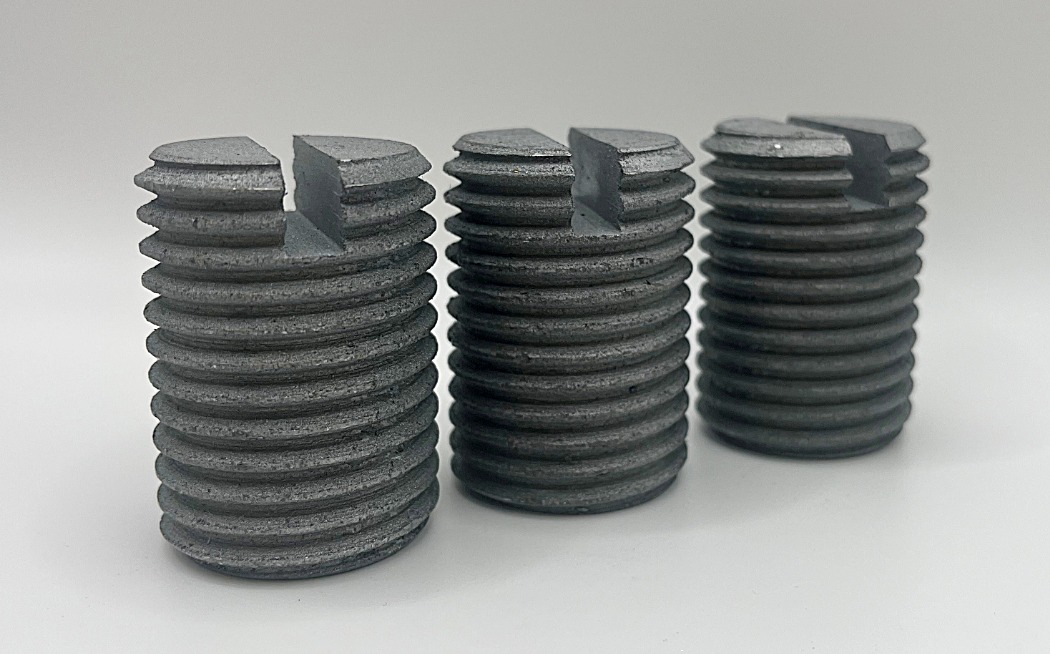

September 16, 2025These M36 × 50 slotted flat point grub screws, also commonly known as a set screw, have been reinforced with hot dig galvanisation.

We expertly manufactured to the metric thread diameter of M36, with a nominal outer diameter of 36mm. The overall length was 50 mm, measured across the fully threaded shank. Grub screws are typically headless and rely entirely on their threaded section for engagement.

The head design featured a slotted drive, allowing the screw to be installed and removed with either a conventional flat-blade screwdriver or compatible slotted bit. This drive style is both a traditional and widely used form of engagement. It provides adequate torque transmission for applications where over-tightening is to be avoided, and where accessibility may be restricted.

The flat point termination at the end of the screw is designed to apply axial holding pressure to the mating component without cutting or penetrating the surface material. This makes it particularly suited for securing parts such as shafts, collars, pulleys, or gear hubs where surface marking is undesirable. This flat end ensures an even distribution of load, which can help minimise localised stress concentrations.

Manufactured from high-grade steel, this grub screw was treated with a hot dip galvanised (HDG) finish. The hot dip galvanising process involves immersing the screw in molten zinc at temperatures of approximately 450 °C. This results in the formation of a robust metallurgical bond between the steel substrate and the zinc coating. Producing a thick and durable corrosion-resistant layer. Compared with electroplated coatings, HDG provides superior long-term protection, particularly in outdoor, marine, or otherwise corrosive industrial environments.

Overall, the M36 × 50 slotted flat point grub screw with a hot dip galvanised finish, is a robust, reliable and corrosion-resistant fastening solution for heavy-duty engineering applications. Combining mechanical strength with protection against environmental degradation.

If you’re looking for advice regarding an ideal coating option for your next project, our teams are ready to assist.

For a comprehensive understanding of the different coating options available, check out our ‘coating options’ news.

Website by FolcraTech

All rights reserved. Privacy policy