December 2, 2025

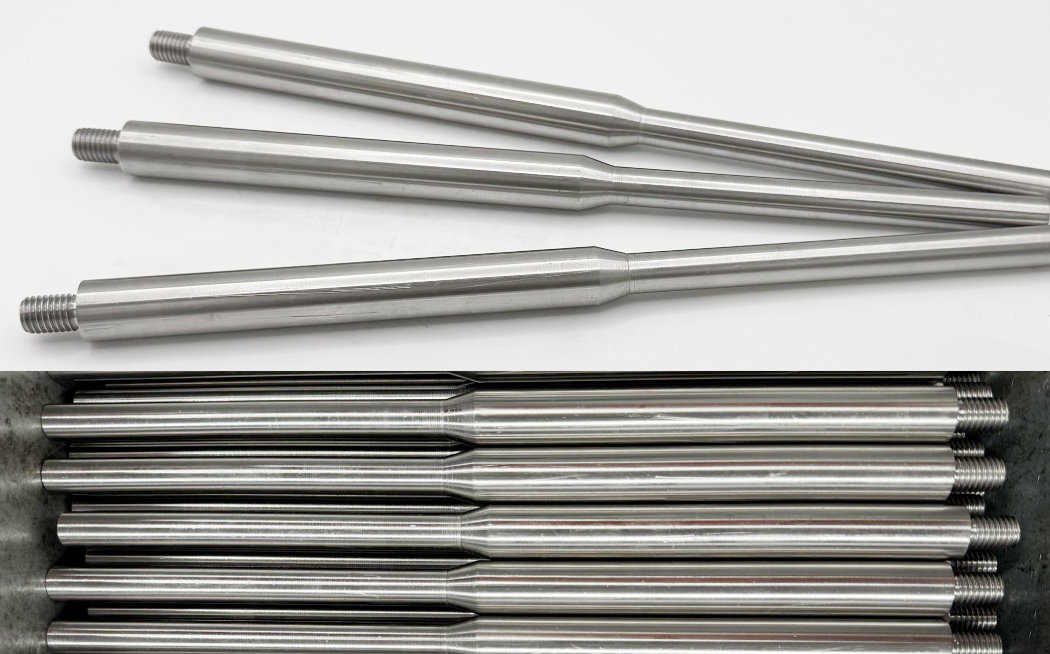

December 2, 2025We’ve recently completed the manufacturing of custom 316 stainless steel threaded rods, featuring a precision-engineered tapered body design.

The tapered profile represents a sophisticated approach to load management, in critical fastening applications. Unlike conventional parallel body threaded rods, the graduated diameter provides progressive load distribution along the fastener’s length. Significantly reducing stress concentrations, whilst maintaining full thread engagement at critical connection points. This design methodology is particularly valuable in applications subject to dynamic loading, thermal cycling, or extreme environmental conditions.

Precision Manufacturing Process

This project exemplifies our capability in translating complex engineering specifications into precision-manufactured fasteners. From initial design consultation and technical review, through to CNC machining and precision thread rolling, each stage is carefully controlled to ensure consistent quality outcomes.

The tapered profile requires specialist machining techniques to maintain accurate angular tolerances whilst preserving thread integrity across the varying diameter. Our team of expert machinists utilise advanced CNC turning centres with live tooling capability, enabling a completion of complex geometries in a single setup. Reducing handling, improving concentricity and ensuring dimensional consistency across the entire production batch.

Thread rolling, rather than thread cutting, is employed wherever possible to enhance fatigue resistance through grain flow alignment and work-hardening of the surface layer. This manufacturing approach significantly improves the mechanical performance of threaded components subject to cyclic loading.

Our Commitment to Excellence

Our commitment extends beyond manufacturing capability. We work closely with design engineers, procurement teams and project managers to ensure fastener specifications align with application requirements.

From technical consultation to final delivery, we strive to ensure every customer receives consistent quality, complete reliability, and the confidence that their fastening solutions are engineered to perform under pressure – all in RAPID time!

Whether you’re specifying components for a unique engineering challenge or require volume production of specialist fasteners. Our manufacturing capability and technical expertise will support your project requirements from concept through to completion.

Our team are ready to assist.

Website by FolcraTech

All rights reserved. Privacy policy