Rapid Industrial Industrial Fasteners are a proud British Manufacturer of fasteners and turned parts.

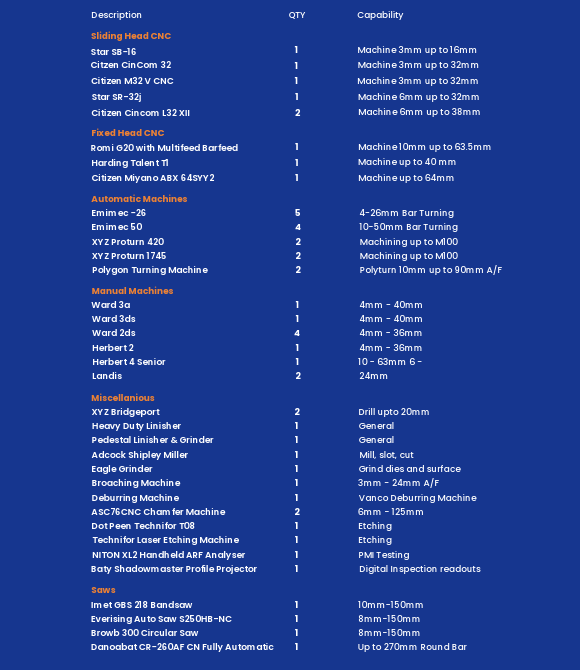

Operating from a separate facility less than ¼ mile away from our distribution centre, we manufacture all standard threaded fasteners in a wide range of steel, stainless steel, brass and exotic alloys including INCONEL, DUPLEX and SUPER DUPLEX. Additionally, our fastener engineers are able to produce complex bespoke parts to drawing and customer specification.

Rapid have been able to apply a highly responsive and service driven culture to our manufacturing philosophy that has been gained from supplying highly demanding end users for over 40 years.

It is of total importance that we do what we say when we say. To that end, we operate a T card system to plan and manage our manufacturing orders so we can be transparent with our customers and communicate regular progress updates.

Contact Now

We manufacture from most material grade, including the following categories:

By manufacturing standard fasteners in material grades that are not routinely available ‘off the shelf’, we make a standard item special!

Rapid Industrial Fasteners manufacture high quality bespoke/special fasteners to our customers exacting specifications and drawing requirements. Customer drawings and manufacturing programs are saved to ensure repeat orders can be set up immediately.

Contact Now

Rapid Industrial Fasteners are ISO:9001(2015) approved and operate through our own modern and innovative quality dashboard. For our standard range of stocked fasteners, we operate full traceability through our internal batch number system and maintain an approved supplier database offering peace of mind to our customers. For our manufactured items, the system is enhanced and all raw material is batch identified, colour coded and PMI tested on arrival and before loading onto machines.

We are committed to continuous improvement and always seeking to improve how we operate and the fluidity of our systems and processes.

With hardwork, dedication and flexibility at the core of our business philosophy, we offer a premium level turnaround service on special orders. We will explore all options, leaving no stone unturned to deliver ‘panic’ orders including operating night and back-to-back shifts. We maintain stock levels of popular material grades and sizes to minimise delays in getting work on the machines. Our manufacturing division also has full access to our distribution resources meaning raw material can be collected same day and sub contract work is delivered and collected same day.

Contact Now

Website by FolcraTech

Copyright 2025. All rights reserved. Privacy policy